Why Ohio’s aerospace industry is soaring ahead of other states

By Terry Troy

The last 18 months have been exciting for Ohio’s aviation and aerospace industry. From landing Joby Aviation’s OEM manufacturing facility more than a year and a half ago to the recent opening of Sierra Nevada’s second MRO (maintenance, repair and operations) hangar in Dayton (as well as the numerous technological developments across our state), Ohio is leading the way when it comes to key elements of the aviation and aerospace industries.

Given the fact that Ohio is considered the birthplace of aviation, this should come as no surprise. But credit should also be given to two affiliated organizations, the Ohio Aerospace Institute (OAI) in Cleveland and Parallax Advanced Research in Dayton. These two organizations are coordinating industry events, benchmarking the industry, fostering the development of research and new technology through academia and, perhaps most importantly, helping entrepreneurs find mentors and funding.

At its headquarters near Cleveland, the OAI recently hosted The Global Aerospace Industry Outlook and Update, an all-day event that highlighted issues pertinent to the aviation, space and defense industries. The conference explored topics impacting the industry from a global perspective, including aerospace and advanced manufacturing, aviation component manufacturing and supply chain needs, advanced air mobility (AAM) and drones, commercial space manufacturing and ventures, and MROs.

Organizations including Airbus, GE, Voyager Space, The Ohio State University, Parker Hannifin and Joby provided updates and opportunities, while representatives of federal and state governments, as well as economic development organizations, shared plans and initiatives.

“The Global Aerospace Industry Outlook and Update provided attendees a better understanding of how the global market impacts and provides opportunities to the commercial, defense and space sectors of the aerospace industry,” Kim Holizna, OAI’s managing director of global development and member programs, says. “Participants gained firsthand insights into current research, development pipelines and business opportunities from aerospace OEMs and industry leaders. Importantly, the event offered businesses a chance to build and strengthen partnerships that will enhance not only Ohio’s aerospace sector but also the overall domestic supply chain.”

Attendees were welcomed by Dennis Andersh, CEO of Parallax Advanced Research, and John Sankovic, president of OAI. They were followed by Tim Sweeney, senior director of Advanced Manufacturing, Aerospace and Aviation for JobsOhio, who offered an update on Ohio’s aerospace landscape.

“We have had some fantastic wins for Ohio,” Sweeney says. “Not only with Joby’s manufacturing plant in Dayton, but Sierra Nevada Corporation opening its second hangar. They also broke ground on hangars three and four and that will directly support and maintain their aircraft. Obviously, they are looking to Ohio as a key state to support their MRO activities.”

In terms of manufacturing, aerospace has sprung back from COVID, with a healthy backlog of potential orders to refill supply chains.

“Ohio is the major supplier to both Boeing and Airbus, giving us a great duopoly when it comes to aviation component manufacturing,” he adds. “But we also have some great companies like Collins Aerospace, Barnes Aerospace, L3Harris and Parker Hannifin, which are key suppliers to the commercial aviation industry as well.”

While commercial aviation component manufacturing is important, Ohio has also focused on supporting companies with MRO operations in our state, Sweeney adds.

“That not only incudes companies like Sierra Nevada, but also companies like GA Telesis,” Sweeney says. “We recently worked on a project with that company at Wilmington Air Park.”

GA Telesis reached an agreement with the Clinton County Port Authority (CCPA), JobsOhio and the Ohio Department of Development to locate its 72,000-square-foot Specialized Procedures Aeroengine Hospital (SPAH) at the Wilmington Air Park. The SPAH facility is capable of inducting more than 200 engines per year focused on those manufactured by General Electric and CFM International.

“We are thrilled to be taking the next step in adding a U.S.-based SPAH to our capabilities,” Russell Shelton, president of the Engine Strategy Group at GA Telesis, said in a press release from the CCPA. “We could not have accomplished this significant milestone without the strategic ATSG partnership and the cooperation of the Clinton County Port Authority and Wilmington Air Park.”

While manufacturing and maintenance are key components of aviation and aerospace, perhaps the most upside potential for the industry comes with AAM and eVTOLs (electrical vertical take off and landing vehicles), Sweeney says. JobsOhio is taking a very active role in how the industry is being formed and regulated.

“We have established five regional teams covering Toledo, Cleveland, Cincinnati, Dayton and Appalachia,” Sweeney says. “Now, we have brought together all the stakeholders including airports, business and industry, academia, and transportation through metropolitan planning organizations. We are trying to figure out where we might be drawing flight routes that will best benefit our communities. So, we are not just focused on manufacturing but a new emerging industry with new aircraft that will bring us even closer to our metro areas.”

In spring of last year, Ohio and Virginia came together and formed a collaboration of eight states to do something to help the AAM industry grow. While competitors in terms of economic development, the teamwork/state approach is designed to help AAM traffic and usage flourish between states. Called the AAM Multistate Collaborative, the organization looks at not only regulatory issues, but also funding of infrastructure.

Twenty-seven states and the National Association of State Aviation Officials (NASAO) held the third meeting of the AAM Multistate Collaborative in The Dalles, Oregon, this past August. The Collaborative’s meeting featured growing participation from additional states and the private sector. The AAM Multistate Collaborative is working toward consensus on key AAM policy issues and how state government can support the roll-out of AAM services as a complement to Federal Aviation Administration efforts and a foundation for industry development.

The Collaborative is working toward finalizing a series of consensus topic papers that will help harmonize state efforts, while acknowledging states’ unique needs, so that the industry can expect consistency across the states and ensure that policies and infrastructure complement federal policy. Previous meetings were hosted by the Virginia Department of Aviation, JobsOhio and NASAO.

“Today, we are up to 32 states and the Choctaw Nation,” Sweeney says. “We are trying to figure out what the policies should be from state to state, what type of funding structure is needed and how our airports will be funded and utilized. While the FAA, NASA, USDOT and others are doing their part at the national level, states will have a very important role to play in this. So, being in the middle of this conversation is very important for us.”

When it comes to the development of new fuels and technology for aerospace, aviation and space travel, Ohio has more than its fair share of innovative entrepreneurs,” Sweeney adds.

Parallax Advanced Research, through funded programs that it manages, such as the Academic Partnership Engagement Experiment (APEX) on behalf of the U.S. Department of the Air Force, helped NEOEx Systems, Inc., a company headquartered in Amherst, in Northeast Ohio, develop a technology that will enable a revolution in unmanned aerial vehicles (UAV) by providing on-board energy and power for extreme long-duration, long-range operations.

Liquid hydrogen has been used as rocket fuel for years. However, generating and storing large amounts of liquid hydrogen is extremely costly because of the cryogenic temperatures needed.

The NEOEx system can generate small quantities of liquid hydrogen to the drone, where another on-board system stores the liquid and directs it to a fuel cell. In turn, that fuel cell produces electricity that powers drone flight. Water and heat are emitted as byproducts, making liquid hydrogen a cleaner energy source than fossil fuels or batteries.

Called the EXTreme ENDurance (EXTEND™) Energy and Power System and the LH2Direct™ Liquid Hydrogen Refueling System, the technologies started garnering the attention of the U.S. military.

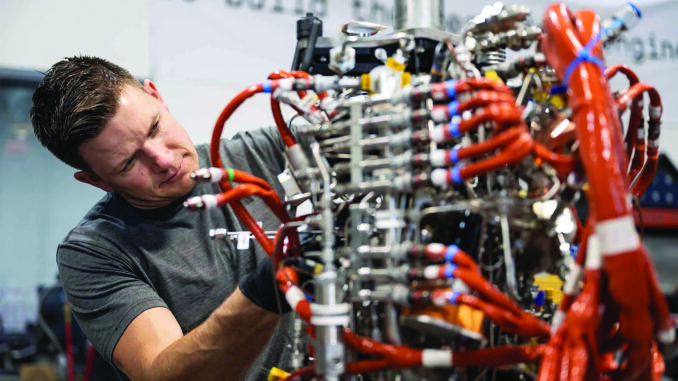

Earlier this year, Ursa Major established a new research and development center near Youngstown, Ohio, to advance additive manufacturing and materials development technology for liquid rocket engines and solid rocket motors. The center represents a capital investment of $14.5 million, which includes $4 million in assistance in the form of a JobsOhio R&D Grant, according to a press release from the company.

Ursa Major worked closely with JobsOhio Network partner Team NEO to secure funding for the expansion, which will be in the new Lake to River region.

Ursa Major has already been 3D printing hardware for propulsion systems in Ohio, so this new R&D center marks an expansion in the state.

Liquid rocket engines and solid rocket motors power platforms that are essential for America’s security. These platforms include high-performance munitions, hypersonic weapons, in-space propulsion systems, and space launch. The company is expanding its R&D efforts in order to meet a growing portfolio of U.S. Department of Defense development contracts.

“The new R&D center in Youngstown takes advantage of Ohio’s manufacturing heritage and uniquely skilled workforce to advance manufacturing in service to our national security,” Joe Laurienti, CEO of Ursa Major, said in the press release. “Raw material access, supply chain, and a vibrant additive manufacturing ecosystem as a result of the America Makes program make Youngstown an ideal home for this center.”

Obviously, larger companies like Parker Aerospace, a business segment of Parker Hannifin, are working on new technologies as well. Parker Aerospace has joined GKN Aerospace and other partners in the H2FlyGHT initiative to develop technology that will set new standards for zero-emission aircraft propulsion systems.

Within H2FLyGHT, Parker Aerospace will be developing thermal management and “‘balance of plant”’ technologies for the fuel cell system, ensuring comprehensive system integration and performance.

“This project is another example that shows how our industry is coming together to reduce emissions,” said Tracy Rice, vice president of technology and innovation for Parker Aerospace. “We are excited to contribute to a better tomorrow by helping to build the next generation of sustainable aircraft and believe in the opportunity presented by advancements in cryogenic hydrogen-electric propulsion.”

When people think about space, they often think about locations such as Houston, Florida or California. Now, Ohio might come to mind.

“Today, Ohio finds itself in a very unique position,” Sweeney says.

“With NASA’s plans to retire the international space station in 2030, the question quickly becomes, ‘What will replace it?’”

“The George Washington Carver space lab, which will be built on The Ohio State University’s campus near the OSU Airport in Columbus, is all about sustainability in space and being able to grow food.

“That’s where the [Agricultural] Department of OSU comes in,” Sweeney adds.

“And that has attracted partners like Hilton Hotels and Northrup Grumman and ZIN Technologies. As NASA and other government agencies turn to commercial ventures to help support our efforts in space, including the return to the moon and eventually on to Mars, our organization is leaning in on ways we can help—and those are the kind of conversations we are starting to have with our aerospace and aviation companies today.”